Views: 0 Author: Site Editor Publish Time: 2025-10-15 Origin: Site

In industrial systems like induction heating, welding, or high-power motor drives, the real challenge isn't just supplying power — it's controlling it precisely, safely, and reliably.

That's where phase-control SCRs (thyristors) come in. But not all SCRs are created equal — the way they are packaged plays a critical role in their performance.

Not all thyristors are built the same. The difference lies in how they handle heat, current, and stress — and that starts with the package design.

Once the SCR conducts, it must handle high current and dissipate significant heat — that's where packaging design becomes critical.

When engineers talk about "controlling power" they don't just mean switching it on or off — they mean regulating it precisely.

From metal furnaces to welding machines and large motor drives, industries depend on phase-control thyristors (SCRs) to deliver smooth, adjustable power without sacrificing reliability.

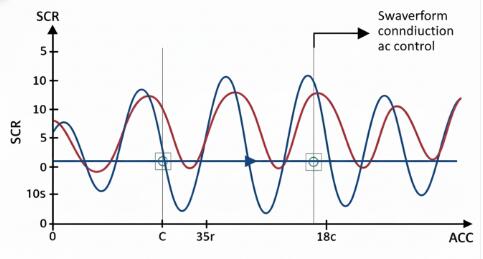

A phase-control SCR regulates power by delaying the conduction angle of an AC waveform. By controlling when the device turns on in each cycle, engineers can fine-tune power for heating, speed control, and voltage regulation.

A silicon-controlled rectifier (SCR) is a type of thyristor that conducts electricity only when its gate is triggered and the current flows in the correct direction.

By adjusting the gate firing angle, engineers can control the portion of the AC waveform that passes through — a method known as phase control.

This makes SCRs perfect for applications like industrial heating, electroplating, and speed control, where fine power adjustment is essential.

However, with great current comes great heat — and that's where packaging matters most.

Stud Package

The semiconductor die is mounted on a threaded stud, offering excellent thermal performance and mechanical robustness. It's widely used in continuous-duty, high-current systems such as rectifiers and regulators.

Disc Package

In disc packages, the chip is sandwiched between two metal electrodes and clamped between heatsinks, allowing double-sided cooling and ultra-low thermal resistance (typically <0.1 K/W).This design gives disc SCRs superior surge handling and reliability, making them ideal for medium-to-high power industrial systems.

Power Module

Combines multiple SCRs or diodes into a single housing, offering compact size and easier integration — but requiring careful thermal design to match disc-type reliability.

More information about packing please check : Understanding Diode And Thyristor Packages: Stud, Disc, And Power Module

Packaging reliability isn't just theory — it's proven by data and research.

Infineon emphasizes that packaging and thermal cycling are key determinants of thyristor lifespan, as outlined in its Quality and Reliability guidelines.

Littelfuse technical notes highlight how proper clamping pressure and contact planarity directly affect SCR performance in field applications (Littelfuse thyristor-fundamental-characteristics of thyristors application-note AN1001)

For moderate current and simple design, choose a stud package.

For high thermal performance and surge endurance, go with disc-type SCRs.

For compact multi-device setups, use power modules with advanced cooling paths.

If your design requires:

Robust simplicity and moderate current, a stud package may be ideal.

High thermal performance and surge capacity, disc-type often becomes indispensable.

Compact integration and multi-component layouts, go with power modules, but only if their thermal design is top-tier.

At PowerPassionElectric, we understand these trade-offs intimately. Our disc-based SCRs are optimized for clean thermal paths, reliable gate structures, and tested endurance. We support you with datasheets, application notes, and thorough integration guidance so your system runs cooler and longer.

Disc-type (or capsule) thyristors mount the silicon chip between two flat metal electrodes, clamped tightly between heatsinks.

This double-sided cooling dramatically reduces thermal resistance — often below 0.1 K/W — and allows the device to handle hundreds or even thousands of amps without overheating.

In short, the disc design turns raw electrical power into controlled, repeatable performance.

Our disc-type SCRs use vacuum-soldered die attach, high-purity ceramic insulation, and precision-machined contacts to ensure long-term thermal stability and minimal conduction loss.

Fast switching, high current handling, and ceramic insulation

Designed for continuous heavy-duty use in industrial power systems.

Reliable and customizable for various current ranges.

Even the best thyristor can face performance issues if the system design isn't right.

Excessive junction temperature, poor clamping pressure, or unstable gate drive signals can all shorten device life.

In a typical industrial system, every 10 °C rise in junction temperature can halve the expected lifetime— a statistic backed by numerous semiconductor reliability studies (Infineon Application Note, 2023).

That's why installation practices matter: clean, flat heatsink surfaces, proper torque, and even pressure distribution ensure the thyristor performs as rated.

At PowerPassionElectric, we take reliability seriously.

Our KP-series SCRs use precision-machined electrodes, low-resistance junctions, and vacuum-soldered die attach technology to minimize thermal stress.

Each unit undergoes high-temperature cycling and surge testing before shipment.

Devices that maintain stable conduction and blocking performance even after thousands of on-off cycles — ideal for OEMs and system integrators seeking long-term stability.

We also provide application guidance for selecting clamping hardware, gate driver design, and cooling configuration — because we know that performance isn’t just about the part, it’s about the whole system.

![]()

PowerPassionElectric is a professional manufacturer of SCR power regulators, thyristor modules, and diode assemblies. Based in Jiangsu, China, we serve global clients in industrial automation, welding, and energy systems with ISO-certified production and comprehensive technical support.